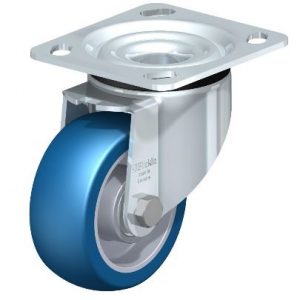

ESD Wheels

Electric discharge can cause significant damage to transport goods and cause injuries to your employees.

Protect yourself and your goods with the ESD wheels from Blickle!

Electrically conductive and antistatic wheels and casters from Blickle

Electrically conductive wheels and casters are important system components in almost all industrial sectors from medical engineering, electrical and semi-conductor industries, to the automotive industry, to hospitals, pharmaceuticals, and other chemical industrial sectors. They are also indispensable in explosion protection zones.

The electrical conductivity of wheels, swivel casters, and fixed casters protects against electrostatic discharge that can be generated by transport equipment or by transported goods. The use of ESD wheels and casters prevents painful electrostatic discharges to the truck user or damage to fragile transported material.

The Blickle product range contains a variety of different wheel series which can also be provided in an ESD design. Alongside rubber, plastics, and metals, polyurethane is also available in a dissipation version as tread material. All products are made in line with the “Made in Germany” quality standard, which also means there is great flexibility with regards to special requests.

An overview of the Blickle product range of electrically conductive wheels and castors can be found here:

Wheels with tread made of thermoplastic rubber

- Electrically conductive

- Non-marking

- Load capacity up to 160 kg

TPA series

- 85° shore A

- Polypropylene wheel centre

Wheels with solid rubber and elastic solid rubber tread

- Electrically conductive

- ALEV series also available in antistatic and non-marking versions

- Load capacity up to 650 kg

ALEV series

- 65° shore A

- Aluminium wheel centre

- 80° shore A

- Nylon wheel centre

V / VE series

- 80° shore A

- Pressed steel wheel centre

- 65° shore A

- Nylon wheel centre

Wheels with thermoplastic polyurethane tread

- Electrically conductive

- Non-marking

- Load capacity up to 325 kg

PATH series

- 94° shore A

- Nylon wheel centre

- Guide roller

- 92° shore A

- Nylon wheel centre

- Guide roller

- 98° shore A

Wheels with cast polyurethane tread

- Anti-static

- Non-marking

- Load capacity up to 1,000 kg

ALTH series

- 92° shore A

- Aluminium wheel centre

ALST series – on request

- 75° shore A

- Aluminium wheel centre

Plastic wheels

- Electrically conductive

- Load capacity up to 1,000 kg

PO series – on request

- Non-marking

- 70° shore D

- Nylon wheel centr

- FPO series – on request

- Non-marking

- 70° shore D

- Guide roller

PPN series – on request

- 70° shore D

- Polypropylene wheel centre

Metal wheels

- Electrically conductive

- Non-marking

- Load capacity up to 15,000 kg

G series

- 180 – 220 HB

- Grey cast iron wheel centre

SVS series

- 190 – 230 HB

- Steel wheel centre

A wheel or a castor is considered to be electrically conductive in line with standards for wheels and castors (DIN EN 12530 – 12533) if its ohmic resistance does not exceed 104 Ω (product code suffix: -EL or -ELS). A wheel or a castor is regarded as having antistatic properties if its ohmic resistance does not exceed 107 Ω (product code suffix: -AS).

To guarantee such requirements, Blickle tests electrically conductive wheels on a special test bench in line with DIN EN 12527. Measurements take place on 3 different locations on the wheel’s tread. This ensures that even in critical applications, any electrostatic potentials that may occur can be safety dissipated via the wheels and castors used. Dirt accumulating on the tread or other environmental influences can have a negative effect on the conductivity during operation and this should be checked by the operator regularly.